Why Do Cars Have Tire-Pressure Monitoring Systems?

Proper tire pressure means a safer and more fuel-efficient vehicle.

Capital One | Aaron Miller

Capital One | Aaron Miller

Tire-pressure monitoring systems (TPMS), which are now mandatory equipment on U.S. passenger vehicles, are intended to alert drivers to air leaks and flat tires.

Although often neglected, correct tire pressure is important, as an under-inflated tire can reduce fuel efficiency, lead to premature wear, and more seriously, separate from the wheel or cause a tire blowout.

The Beginnings of Tire-Pressure Monitoring

TPMS first surfaced in Europe in the mid-’80s on the Porsche 959 supercar (which wasn’t street legal in the U.S.). It used sensors built into the wheels.

General Motors introduced tire-pressure monitoring to the U.S. as an option on the 1989 Chevy Corvette. Called the low-tire-pressure warning system (LTPWS), it relied on a transmitter strapped to the inside of the wheel with a metal band.

What Prompted the Wide Adoption of TPMS?

TPMS continued to gain popularity as an option and occasionally as standard equipment on various models. The increasing prevalence of run-flat tires played a part in its adoption; that’s because a punctured run-flat will continue to support a vehicle, and the driver may not notice a loss of pressure—hence the need for TPMS. In fact, in the early 1990s, GM’s LTPWS allowed Chevy to offer run-flats on the Corvette for the first time.

The big impetus for change, however, came in the late 1990s, when a spate of Ford Explorers equipped with Firestone rubber crashed due to tire failure. Dozens if not hundreds of people died, Ford and Firestone pointed the finger at each other while recalling millions of tires, and consumers wanted answers. The resulting investigation led Congress to enact the Transportation Recall Enhancement Accountability and Documentation (TREAD) Act, in 2000.

Among other things, this legislation required the installation of tire-pressure monitoring systems on all four tires of all new passenger vehicles and light trucks sold from September 2007. The thinking was, if vehicles had TPMS, drivers would learn about and address a low-tire-pressure situation before it became a safety issue.

Tire-Pressure Monitoring Today

There are two main ways to monitor tire pressure: indirectly and directly. Indirect TPMS is simpler and uses data from wheel-speed sensors to determine the relative pressure of the tire (an underinflated tire will have a smaller diameter, which the vehicle’s computers can detect). This method does not provide the pressure measurement at each wheel but instead alerts the driver when a particular tire is low.

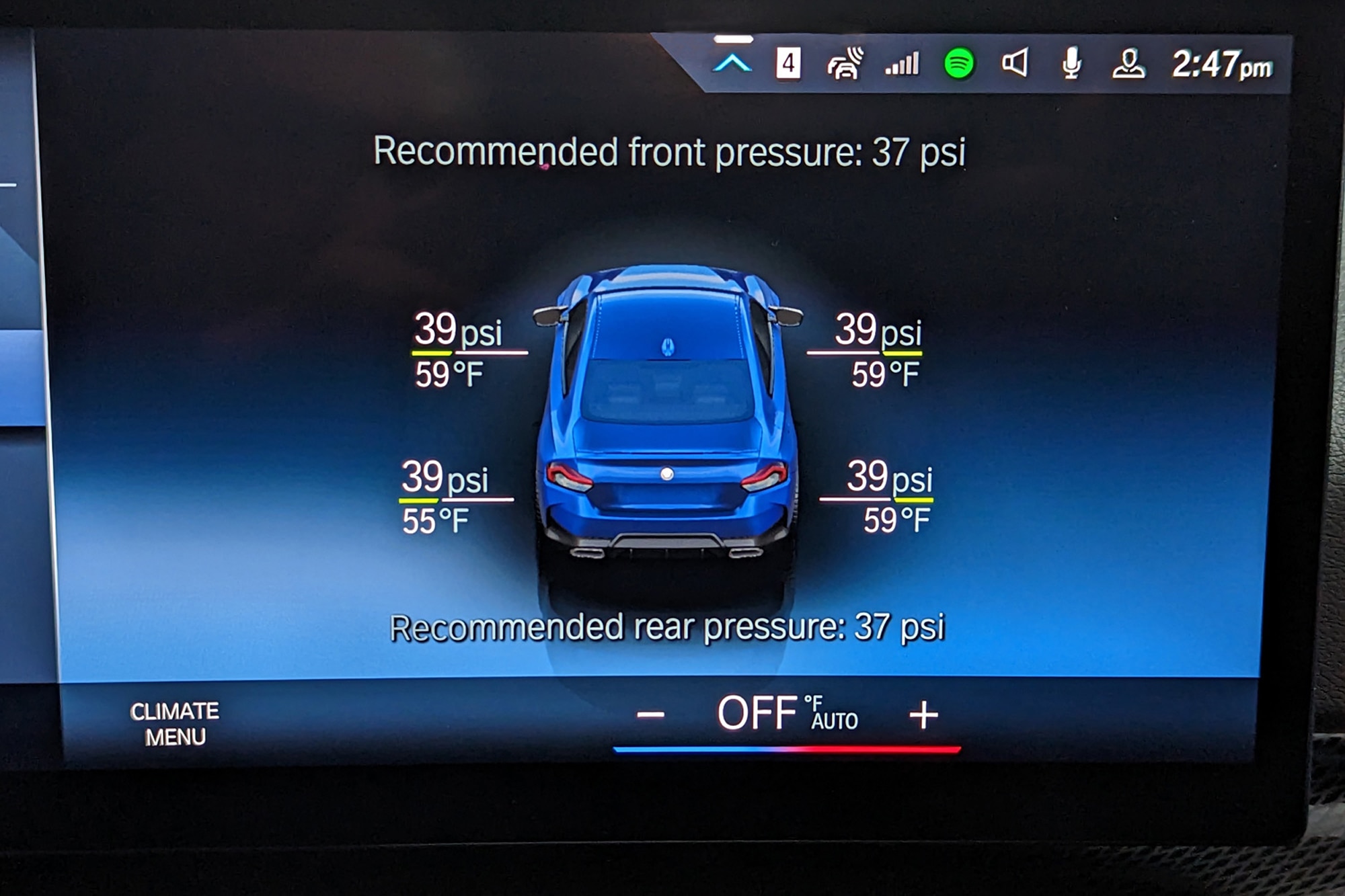

Direct TPMS uses a sensor installed on the wheel or as part of the valve stem to measure the exact pressure in the tire. It periodically transmits the information wirelessly to a receiver on the vehicle. The driver can usually access these numbers through an interior display. Some vehicles with direct sensors will even provide feedback while someone is filling the tires. Nissans, for instance, will flash the lights to indicate the start of inflation and chirp the horn to tell you when to stop.

Written by humans.

Edited by humans.

David Gluckman

David GluckmanDavid Gluckman has over a decade of experience as a writer and editor for print and digital automotive publications. He can parallel park a school bus, has a spreadsheet listing every vehicle he’s ever tested, and once drove a Lincoln Town Car 63 mph in reverse. When David’s not searching for the perfect used car, you can find him sampling the latest gimmicky foodstuffs that America has to offer.

Related articles

View more related articles